Product

nameSkiving machine, Vacuum cleaner

5

|

Example of use |

・Process of folding hem up ? folding hem up after cutting It would become easy to fold hem up because of getting |

|---|

- We are only one company for producing leather skiving machine in Japan.

We produce not only

main body of machine but also knife in our factory, and carry out thorough quality control. - Not only small lot product but also mass product, we will produce numbers of machines depending on

your frequency of use and any materials, also automatic machines. - The mechanical structure is paid attention to the functional aspect as well as safety and maintenance

for user to easy to use.

Size of NP-202 complete set ; head, table, stand, clutch motor

| Net weight | 100kg | Gross weight | 110kg |

|---|---|---|---|

| Measurement (Net) |

1200L×530W×1200H(mm) | Measurement (Gross) |

*It needs table and driving motor for using skiving machine.

Mechanical specification for skiving machine (standard type)

|

Max skiving |

50mm | Max skiving degree |

10° |

|---|---|---|---|

| Max skiving thickness |

7mm | Recommen- dation clutch motor |

200~400W(4P) |

| The diameter for recommen- dation clutch motor |

φ50~φ60 |

Additional explanation

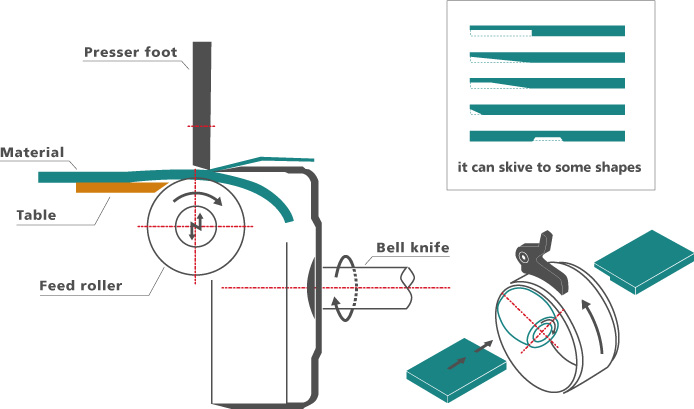

After setting materials, the material engages into the space between feed roll and presser foot, then it is skived by knife edge. Basically, the necessary size of material is put up above and the wastes go down after skiving. The skiving thickness depends on the height of presser foot, and also the machine is equipped with feed roll with spring for dealing with variation in the thickness of leather or rough materials.

| Machine specification |

Max skiving width |

Main usage | |

|---|---|---|---|

| NP-201 | Leather skiving machine (Patented type) | 50mm | For making shoes and bags |

| NP-202 | Leather skiving machine | 50mm | For making shoes and bags |

| NP-S1 | Standard skiving machine(for overseas) | 50mm | For making shoes and bags |

| NP-10 | Skiving machine for thick leather | 50mm | For hard, thick and rough leather |

| NP-1028D | Skiving machine with feed motor | 50mm | For making shoes and bags |

| NP-217 | Skiving machine for Tubular upholstery handles | - | For all kinds of bags |

| Slant skiving set | NP215 | 10mm(standard) | Leather strap, Jointed part of leather |

| NP-13 | Attachment of skiving machine | - | - |

| 301A 301 | Consumable parts for skiving machine | - | - |

| 416 Emery wheel | Consumable parts for skiving machine | - | - |

| Presser foot | Consumable parts for skiving machine | - | - |

| 513 feed roller | Consumable parts for skiving machine | - | - |

| NP-2051S | Vacuum cleaner for leather skiving machine(Standard) | - | - |

| NP-2051KS | Vacuum cleaner for leather skiving machine(High powered type) | - | - |

| NP-S1G | Standard skiving machine(for overseas) | 50mm | For making shoes and bags |

| NP-S3TC | leather goods | 50 | - |